What Challenges Does the Automotive Industry Face with the Adoption of Automation?

Industrial automation is revolutionizing the automotive industry, significantly changing manufacturing processes, supply chain management, and vehicle technology. Despite its numerous benefits, the adoption of automation presents several challenges.

This blog delves into the primary obstacles the automotive industry faces as it integrates automation into its operations.

High Initial Investment Costs

One of the most significant challenges in adopting automation is the high initial investment required. Implementing automated systems involves purchasing advanced machinery, robotics, and software, which can be prohibitively expensive, especially for small and medium-sized enterprises (SMEs).

The cost of acquiring and installing automation equipment can be a major financial burden. Companies must carefully calculate the return on investment (ROI), considering the long-term benefits versus the upfront costs.

Workforce Displacement and Skill Gaps

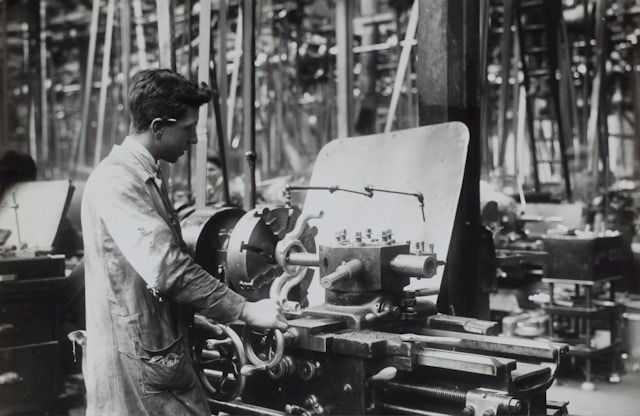

Automation also leads to concerns about workforce displacement as machines and robots take over tasks previously performed by humans. This shift requires employees to adapt to new roles, often necessitating reskilling and upskilling. There is a real fear of job losses among the workforce.

Companies must invest in training programs to equip employees with the skills needed to operate and maintain automated systems. The development of new skills is crucial for both job retention and the efficient operation of automated processes.

Integration with Existing Systems

Integrating new automated systems with existing manufacturing processes and IT infrastructure can be complex. Compatibility issues may arise, requiring significant modifications to current systems.

Ensuring new automation technologies work seamlessly with legacy systems is essential to avoid operational disruptions. The transition period must be managed carefully to minimize disruptions and maintain production efficiency.

Cybersecurity Threats

As automation increases, so does the potential for cybersecurity threats. Automated systems are often connected to the internet, making them vulnerable to cyber-attacks that can disrupt operations or lead to data breaches. Identifying and mitigating potential vulnerabilities in automated systems is crucial for maintaining operational integrity.

Implementing robust security measures to protect sensitive data is necessary to safeguard against cyber threats and ensure the reliability of automated processes.

Regulatory Compliance

The automotive industry is heavily regulated, and the adoption of automation introduces new regulatory challenges. Companies must ensure that their automated processes comply with industry standards and government regulations.

Staying updated with changing regulations related to automation is essential to avoid legal issues and financial penalties. The financial impact of meeting regulatory requirements can be significant, adding to the overall cost of automation.

Quality Control Issues

While automation can enhance precision and efficiency, it can also lead to quality control challenges. Automated systems require constant monitoring and maintenance to ensure they produce high-quality products. Implementing robust quality control measures in automated processes is essential to maintain product standards.

Regular maintenance is necessary to prevent defects and ensure consistent quality, which can add to the operational costs and complexity.

Supply Chain Disruptions

The integration of automation can lead to supply chain disruptions, especially if suppliers and partners are not equally advanced in their automation capabilities. Coordination and communication become critical to maintaining a smooth supply chain.

Ensuring all parts of the supply chain are aligned with automation efforts is vital for operational continuity. Developing strategies to mitigate potential supply chain disruptions is necessary to avoid production delays and financial losses.

Ethical and Social Implications

The widespread adoption of automation raises ethical and social concerns. Companies must navigate the social impact of automation on local communities and address ethical considerations related to job losses and economic inequality. Additionally, technologies like 5G Home Internet can further complicate these dynamics by accelerating automation and connectivity, necessitating thoughtful integration strategies.

Balancing automation benefits with social impacts is a complex challenge. Addressing the ethical implications of replacing human labor with machines is essential for maintaining corporate social responsibility and public trust.

Adaptation to Rapid Technological Changes

The pace of technological advancement in automation is rapid, making it challenging for companies to keep up. Staying ahead requires continuous investment in the latest technologies and innovation. Keeping up with the latest developments in automation technology is crucial for maintaining a competitive edge. Investing in research and development to remain competitive is necessary to leverage the full potential of automation.

Environmental Concerns

Automation can contribute to increased energy consumption and environmental impact. Companies need to consider the environmental implications of their automated systems and strive for sustainable automation solutions.

Developing energy-efficient automated systems is essential for reducing the environmental footprint. Implementing eco-friendly practices in automation is necessary to align with global sustainability goals and regulatory requirements.

Conclusion

The adoption of automation in the automotive industry presents numerous challenges, from high initial costs and workforce displacement to cybersecurity threats, regulatory compliance, and the integration of complex systems like the Motor Control Center.

However, by addressing these challenges proactively, companies can harness the benefits of automation to enhance productivity, quality, and competitiveness. Ensuring a smooth transition requires strategic planning, investment in employee training, robust cybersecurity measures, and a commitment to ethical and sustainable practices.