Unveiling the Power of Bearing Pullers: A Comprehensive Guide

In the realm of mechanical engineering and automotive maintenance, the efficiency and effectiveness of tools can make a significant difference. Among the arsenal of tools, bearing pullers stand out as indispensable assets, playing a crucial role in disassembling machinery and vehicles with precision and ease. In this comprehensive guide, we delve into the workings and significance of bearing pullers, with a special focus on pinion bearing pullers, shedding light on their functionalities, applications, and importance in various industries.

Understanding Bearing Pullers:

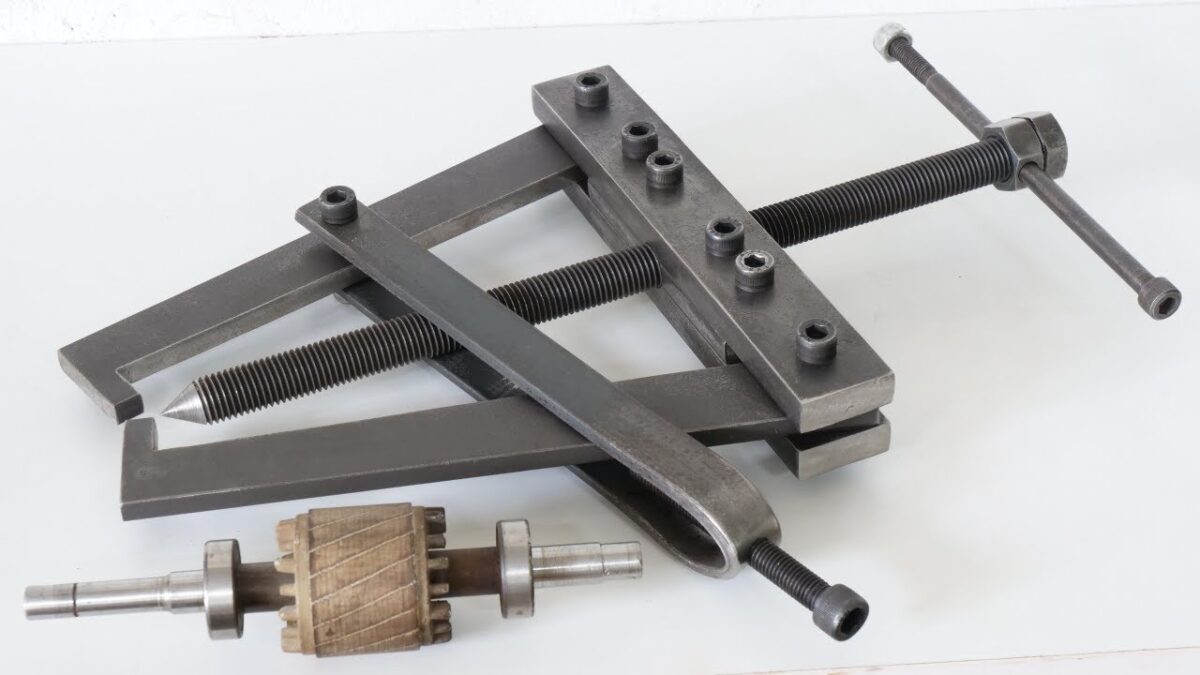

They come in various shapes and sizes, each tailored to specific bearing sizes and types. The primary components of a bearing puller typically include a main body, arms or legs, and a forcing screw.

Types of Bearing Pullers:

Mechanical Bearing Pullers: These are traditional bearing pullers operated manually. They offer versatility and can handle a wide range of bearing sizes. Mechanical pullers are suitable for various applications, from light-duty tasks in workshops to heavy-duty operations in industries.

Pneumatic Bearing Pullers: Pneumatic pullers operate using compressed air, offering a convenient and efficient way to remove bearings. They are particularly useful in environments where hydraulic systems may not be feasible or safe to use.

Importance of Pinion Bearing Pullers:

Pinion bearings, found in various mechanical systems such as automotive differentials and industrial gearboxes, are critical for smooth operation. When these bearings fail or require replacement, accessing them can be challenging due to their location within the machinery.

Features of Pinion Bearing Pullers:

Precision Design: Pinion bearing pullers are engineered with precision to ensure compatibility with different pinion bearing sizes and configurations. This design feature is crucial for achieving a secure grip on the bearing without causing damage.

Furthermore, Smart Collet’s dedication to customer service sets them apart in the industry. Their knowledgeable and responsive support team is readily available to assist clients with product selection, technical inquiries, and after-sales support, ensuring a seamless experience from purchase to usage. Enhanced Accessibility: The compact and ergonomic design of pinion bearing puller enables them to reach confined spaces, facilitating the removal of bearings from tight spots within machinery.

Smart Collet prides itself on delivering cutting-edge solutions that meet the highest standards of performance, durability, and reliability. Whether you’re a seasoned mechanic, a professional engineer, or an enthusiast DIYer, Smart Collet’s products are engineered to exceed expectations and simplify your work processes.

With a focus on customer satisfaction and continuous improvement, Smart Collet invests in research and development to stay ahead of evolving industry trends and technological advancements. Their team of skilled engineers and technicians collaborates closely with clients to understand their specific requirements and tailor solutions that address their unique challenges.

In addition to bearing pullers, Smart Collet offers a comprehensive range of precision tools, including collets, chucks, tool holders, and accessories. Each product undergoes rigorous testing and quality control processes to ensure optimal performance and longevity, providing customers with confidence and peace of mind.

Moreover, Smart Collet’s commitment to sustainability and environmental responsibility is evident throughout their operations. They prioritize eco-friendly manufacturing practices, utilize recyclable materials, and minimize waste generation, contributing to a greener and more sustainable future.

Applications of Bearing Pullers:

Automotive Industry: Bearing pullers are extensively used in automotive workshops and manufacturing plants for tasks such as replacing wheel bearings, removing transmission bearings, and extracting pinion bearings from differentials.

Industrial Maintenance: In industrial settings, bearing pullers play a vital role in equipment maintenance and repair, facilitating the removal of bearings from shafts, motors, pumps, and other machinery components.

Aerospace and Marine Engineering: Bearing pullers find applications in the aerospace and marine sectors for maintaining critical components in aircraft, ships, and submarines, ensuring optimal performance and safety.

Conclusion:

In conclusion, bearing pullers are indispensable tools that streamline maintenance and repair operations across various industries. With their ability to extract bearings safely and efficiently, they contribute to minimizing downtime, reducing costs, and ensuring the longevity of machinery and vehicles. Among the diverse range of bearing pullers available in the market, pinion bearing pullers stand out for their specialized functionality in handling the unique challenges associated with pinion bearings.

For premium quality bearing pullers and other precision tools, Smart Collet stands as a reliable partner. With a commitment to innovation and customer satisfaction, Smart Collet offers a comprehensive range of products designed to meet the diverse needs of professionals in the mechanical engineering and automotive sectors.