The Magical Advancements in Toy Molding: A Study on Indiana’s Contribution

toy molding has revolutionized the manufacturing industry, allowing for the production of intricate and durable toys. This research article explores the advancements in toy molding techniques and focuses on Indiana’s significant contribution to this field.

Indiana’s Role in Toy Molding Innovation

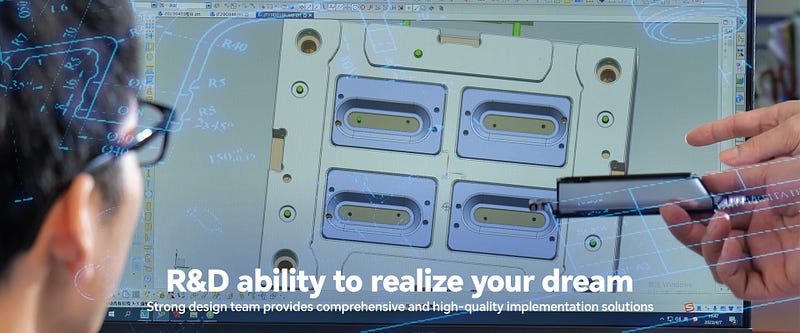

Indiana has emerged as a key player in the toy molding industry, with several companies leading the way in innovation. One such company is JVTECH, which specializes in developing cutting-edge toy molds that ensure high-quality products.

JVTECH employs state-of-the-art technology and highly skilled professionals to create molds that meet stringent safety standards while maintaining aesthetic appeal. Their commitment to precision engineering has made them a trusted partner for many toy manufacturers worldwide.

The Liquid Silicone Molding Process

A notable advancement in toy molding is the utilization of liquid silicone molding process. This technique involves injecting liquid silicone into a mold cavity under high pressure, resulting in detailed and flexible toy components.

This process offers numerous advantages over traditional methods, including enhanced design flexibility, shorter production cycles, and improved product durability. The use of liquid silicone also ensures that toys are safe for children by being free from harmful chemicals such as phthalates or BPA.

Conclusion

In conclusion, Indiana plays a pivotal role in advancing toy molding techniques through companies like JVTECH. Their expertise and dedication have contributed significantly to improving both the quality and safety of toys produced today.

The adoption of innovative processes like liquid silicone molding further enhances these advancements by offering increased design possibilities and safer materials for children’s toys. As we continue to witness progress within this field, it is evident that Indiana will remain at the forefront of shaping the future of toy manufacturing.