Industrial Machinery Installation: A Guide to Seamless and Efficient Setup

Industrial machinery plays a pivotal role in manufacturing, production, and other heavy-duty industries. Whether you’re setting up a new factory, upgrading existing equipment, or expanding production capabilities, industrial machinery installation is crucial to the success of your operations. Proper installation ensures that your machines run efficiently, safely, and at their optimal capacity, ultimately leading to increased productivity and cost savings.

In this guide, we’ll explore the key steps involved in Industrial Machinery Installation, the benefits of professional installation services, and important considerations to keep in mind for a smooth and effective setup.

Why Industrial Machinery Installation Matters

Installing industrial machinery is not a simple task. It involves complex processes that require expertise in electrical, mechanical, and structural systems. A poorly installed machine can lead to equipment failure, costly downtime, safety hazards, and even damage to other machinery. Here’s why proper installation is essential:

Enhanced Performance Industrial machinery that is installed correctly operates more efficiently. Misaligned machines or incorrect wiring can lead to poor performance, resulting in wasted energy and reduced productivity.

Safety Compliance Proper installation ensures that the machinery meets safety standards and regulations. Correct installation minimizes the risk of accidents, such as machinery malfunctions, electrical fires, and worker injuries.

Longer Equipment Lifespan Properly installed machinery is more likely to have a longer lifespan. Misalignment, poor calibration, and improper setup can lead to unnecessary wear and tear on components, reducing the lifespan of your machinery.

Reduced Downtime Correct installation helps avoid equipment failures and downtime. When machines are properly installed, they function smoothly, reducing the chances of breakdowns and costly repairs.

Cost Savings While hiring professional installation services may seem like an additional cost, it can save you money in the long run. Efficient installation minimizes maintenance needs and ensures that your equipment operates at full capacity.

Key Steps in Industrial Machinery Installation

Industrial machinery installation involves several key steps that must be carefully planned and executed. Here’s a breakdown of the typical installation process:

Pre-Installation Planning

Before starting the installation process, thorough planning is essential. This stage involves:

-

Site Assessment: Evaluating the site to determine the best location for the machinery. This includes checking for space, floor load capacity, proper ventilation, electrical requirements, and access to necessary utilities.

-

Preparation of Utilities: Ensuring that all utilities, such as electricity, water, compressed air, and gas lines, are properly installed and ready for connection to the machinery.

-

Machine Delivery and Storage: Properly handling and storing the machinery before installation. Heavy equipment should be stored in a safe area to avoid damage.

Mechanical Installation

This step involves the physical setup of the machinery. The process includes:

-

Positioning: Placing the machinery in the designated area based on the site assessment. This may involve using cranes or other heavy-lifting equipment to move large machines into place.

-

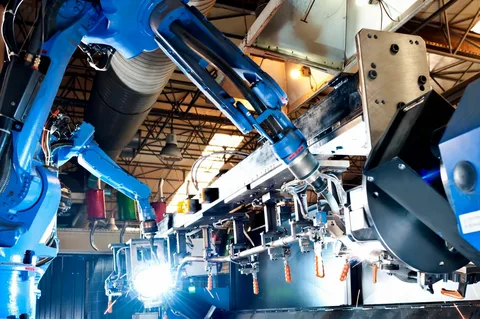

Alignment: Ensuring the machine is level and properly aligned with other components, such as conveyors, assembly lines, or robotic arms.

-

Mounting and Fixing: Securing the machinery to the foundation or base to prevent vibrations and movement during operation.

Electrical and Wiring Connections

Once the machinery is in place, the electrical connections are made. This includes:

-

Connecting Power Supply: Ensuring that the equipment is connected to the proper power source. Electrical wiring must comply with industry standards and safety codes.

-

Wiring and Controls: Installing control panels, sensors, and other electrical components that will be used to operate the machinery. Proper wiring ensures safe and efficient operation.

-

Testing Circuits: Verifying that all electrical components are correctly wired and functioning.

Calibration and Setup

After the machinery is installed and connected, it must be calibrated and set up for operation:

-

Initial Calibration: Adjusting the machinery to ensure it operates within the specified parameters. This includes setting speed, pressure, temperature, and other settings depending on the machine’s functions.

-

Software Configuration: If the machinery uses a computerized control system, it must be configured to work with your specific operational needs.

-

Operational Testing: Running tests to verify that the machinery is functioning correctly. This ensures that all components are working together as intended.

Training and Handover

Once the machinery is installed, trained personnel are required to operate it safely and efficiently. Training typically involves:

-

Operator Training: Educating operators on how to use the machine properly, including understanding its controls, settings, and maintenance needs.

-

Safety Protocols: Ensuring that operators understand the safety protocols associated with the machinery. This includes emergency shutdown procedures and safe handling practices.

-

Documentation Handover: Providing the owner or operator with all the necessary manuals, service guides, and warranties.

Benefits of Professional Industrial Machinery Installation Services

While DIY installation may seem like a cost-effective option, hiring professionals for industrial machinery installation offers several advantages:

Expertise and Experience Professional installers have the technical knowledge and experience to handle complex machinery. They are well-versed in understanding the intricacies of different types of equipment and know how to deal with challenges during the installation process.

Quality and Precision Professionals ensure that every step of the installation is performed with the highest level of quality and precision. This results in more accurate installations and a higher quality final product.

Safety and Compliance Professional installers are trained to meet all industry safety standards and ensure that the machinery installation complies with local regulations. This minimizes the risk of accidents and ensures your facility passes inspections.

Time Efficiency Industrial machinery installation can be time-consuming, especially if there are challenges in the process. Professional installation services can complete the setup faster and more efficiently, reducing downtime.

Ongoing Support Many professional installation services offer ongoing support and maintenance. This ensures that your machinery continues to operate smoothly after installation and provides a point of contact for troubleshooting any issues.

Key Considerations When Hiring Industrial Machinery Installation Services

When choosing a service provider for industrial machinery installation, consider the following:

Experience and Expertise: Choose a company with experience in installing the type of machinery you use. They should have a proven track record of successful installations.

Reputation and Reviews: Check customer reviews and testimonials to gauge the company’s reliability and quality of service.

Licensing and Certification: Ensure that the company is properly licensed and certified to perform installations according to industry standards.

Cost and Timeline: Obtain quotes from multiple providers and ensure that the installation timeline aligns with your production schedule.

Conclusion

Industrial machinery installation is a complex process that requires careful planning, precision, and technical expertise. Whether you’re setting up new machinery, upgrading existing equipment, or expanding your operations, professional installation services ensure that your machines run efficiently, safely, and effectively.

By investing in proper installation, you’ll enhance machine performance, reduce downtime, extend equipment lifespan, and improve overall productivity. Choose experienced and certified professionals for a seamless installation that supports your business’s success.