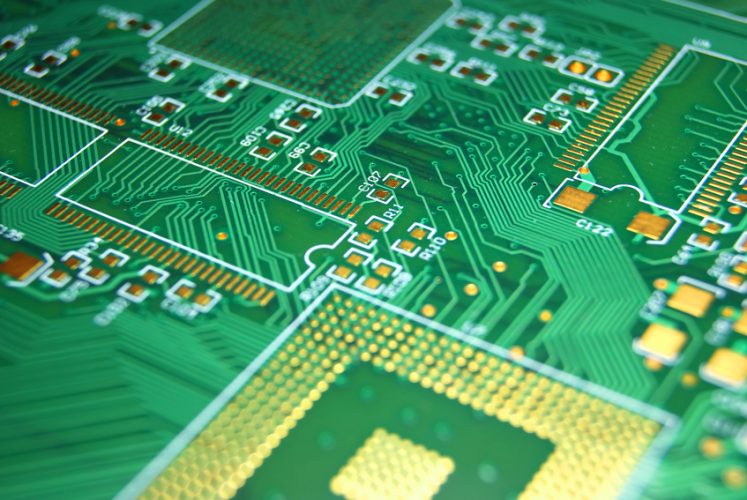

How PCB Prototyping Boosts Precision in Tech Design

In the rapidly evolving world of technology, precision is paramount. Designers and engineers face the challenge of creating intricate electronic systems that not only meet functionality but also maintain the highest standards of accuracy. PCB prototyping has emerged as a vital process in achieving these goals. By allowing for the rapid development and testing of printed circuit boards, prototyping enhances precision in tech design. This article explores how PCB prototyping boosts precision and why it’s essential for modern technology development.

Understanding PCB Prototyping

PCB prototyping involves the creation of a preliminary version of a printed circuit board to test and validate a design before full-scale production. It allows engineers to examine the functionality of their designs, make necessary adjustments, and refine their work based on real-world testing and feedback. The importance of this process cannot be overstated, as it directly impacts the quality and reliability of electronic devices.

The Role of Precision in Tech Design

Precision in tech design is crucial for several reasons:

Functionality: Precise designs ensure that electronic devices perform as intended. Any deviation can lead to malfunctions, affecting the user experience.

Reliability: Products that are designed with precision are less likely to fail during operation, which is particularly critical in industries like healthcare and aerospace.

Cost Efficiency: Achieving precision in the early stages of design can reduce the costs associated with rework, recalls, and warranty claims.

Given these factors, incorporating PCB prototyping into the design process is essential for ensuring that tech products meet the necessary precision standards.

How PCB Prototyping Enhances Precision

Early Detection of Design Flaws

One of the primary benefits of PCB prototyping is the ability to identify design flaws early in the development process. Traditional methods of circuit board design may not reveal potential issues until after production, leading to costly adjustments. By creating prototypes, designers can:

- Conduct functional tests to verify that all components work as intended.

- Analyze the layout for signal integrity and interference.

- Evaluate thermal management solutions to prevent overheating.

These early tests provide valuable insights that can be addressed before mass production, resulting in more precise final products.

Iterative Design Process

PCB prototyping promotes an iterative design process where engineers can make adjustments based on real-time feedback. This allows for multiple revisions of the design, which can greatly enhance precision. The iterative process includes:

- Modifying layouts based on testing results.

- Reassessing component placements to optimize performance.

- Experimenting with different materials and techniques.

The ability to iterate quickly means that any errors can be corrected swiftly, leading to a more refined and precise end product. Companies can effectively balance speed and accuracy, ensuring that they stay competitive in a fast-paced market.

Enhanced Collaboration and Communication

Effective collaboration is key to achieving precision in tech design. PCB prototyping fosters communication between engineers, designers, and stakeholders. By providing a tangible representation of the design, prototypes enable:

- Clear discussions around functionality and design intent.

- Visual feedback can help clarify complex ideas.

- Cross-departmental input, which may identify overlooked precision issues.

Such collaboration ensures that everyone involved has a shared understanding of the project, leading to a more cohesive approach to design and a final product that meets precision requirements.

Real-World Testing Conditions

Prototypes allow for testing in real-world conditions, which is crucial for achieving precision in design. Designers can assess how their PCBs perform under various conditions, such as:

- Different temperatures and humidity levels.

- Vibration and shock environments.

- Electromagnetic interference.

These tests reveal how a product will function in its intended environment, enabling designers to make necessary adjustments to enhance precision. Without this step, many potential issues may go unnoticed until after production, leading to costly changes and potential product failures.

Cost-Effective Prototyping Technologies

Advancements in prototyping technologies have made PCB prototyping more cost-effective than ever. Techniques such as 3D printing and CNC machining allow for rapid production of prototypes, reducing lead times and costs. This affordability encourages companies to prototype more frequently, leading to:

- Increased experimentation with designs.

- More opportunities to refine precision.

- Lower risks associated with the development of complex tech products.

Companies can now invest in multiple iterations of their designs without breaking the bank, promoting a culture of precision-driven innovation.

Conclusion

PCB prototyping plays a crucial role in enhancing precision in tech design. By enabling early detection of design flaws, promoting an iterative design process, fostering collaboration, providing real-world testing conditions, and utilizing cost-effective technologies, prototyping ensures that products meet the highest standards of accuracy and reliability.

If you’re looking to elevate your design process and enhance the precision of your electronic products, click this link here now to explore more about effective prototyping strategies and solutions. The investment in PCB prototyping is an investment in quality, reliability, and ultimately, the success of your tech products.

Embrace the power of PCB prototyping and take the first step toward precision-driven design today! Whether you’re a startup looking to break into the market or an established company seeking to innovate, PCB prototyping can be your key to success.