How Can Laser Cutting Enhance the Efficiency of Sheet Metal Enclosure Manufacturing?

How important is efficiency when it comes to manufacturing sheet metal enclosures? In today’s competitive market, achieving higher productivity while maintaining quality is essential for businesses to stay ahead. This is where advanced technologies like laser cutting come into play. Laser cutting has transformed the way custom metal enclosures are produced, offering unparalleled precision, speed, and cost-effectiveness. In this blog, we will explore how laser cutting can significantly enhance the efficiency of manufacturing sheet metal enclosures and why partnering with a reliable sheet metal cutting service is key to unlocking these benefits.

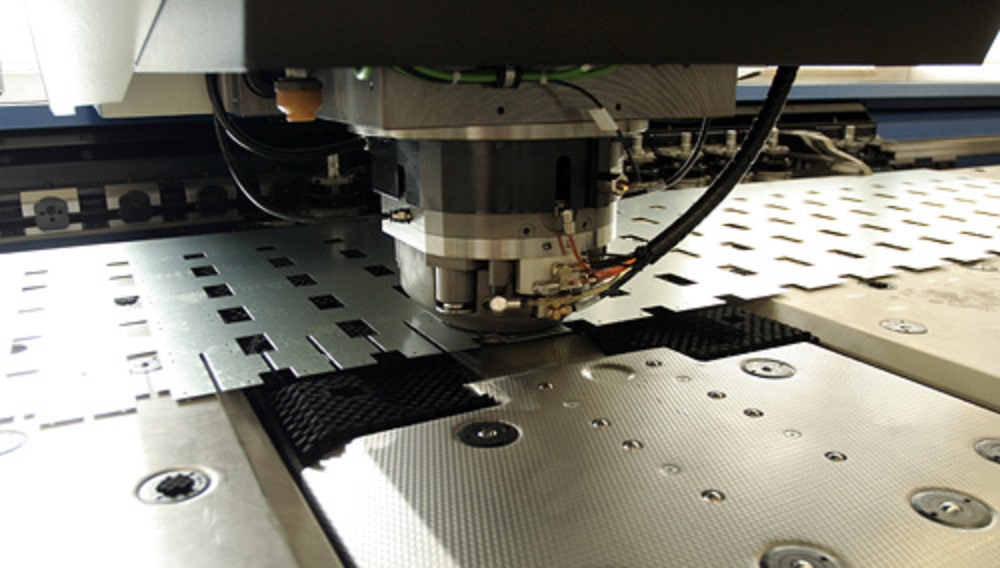

Laser Cutting in Manufacturing Sheet Metal Enclosures

Laser cutting technology has revolutionized the fabrication of sheet metal enclosures by providing manufacturers with the tools to produce intricate and precise designs that meet exact specifications. Traditional methods often fell short when it came to cutting complex shapes or ensuring uniformity across large production runs. However, laser cutting technology has bridged this gap, allowing manufacturers to achieve high-quality results consistently.

The process of laser cutting involves using a focused laser beam to melt, burn, or vaporize material, resulting in clean and precise cuts. This technology is particularly well-suited for custom metal enclosures because it can handle various materials, including steel and stainless steel, without requiring manual adjustments. Whether you’re working with thin sheets or thick plates, laser cutting ensures that each enclosure is produced with exacting detail, which is crucial for both functionality and aesthetics.

How Professional Laser Cutting Increases the Efficiency of Sheet Metal Enclosure Manufacturing

One of the most significant advantages of professional laser cutting in sheet metal enclosure manufacturing is the combination of speed, precision, and cost-effectiveness. Let’s break down how these factors contribute to greater efficiency:

- Precision and Accuracy: In the world of custom metal enclosures, precision is everything. Whether it’s a simple box or a complex enclosure with multiple cutouts, professional laser cutting ensures that every detail is executed flawlessly. This high level of precision reduces the chances of errors, meaning less rework and wastage and, ultimately, faster project completion.

- Increased Production Speed: Time is a critical factor in manufacturing. The faster you can produce high-quality enclosures, the more competitive you become. Laser cutting excels in this area, as it significantly reduces the time needed to cut and shape sheet metal enclosures. Unlike traditional cutting methods, which may require multiple passes or manual interventions, laser cutting completes the task in a single, swift operation. This increase in speed doesn’t compromise quality, allowing for quick turnarounds even for large-scale orders.

- Cost-Effectiveness: Efficiency in manufacturing is not just about speed and precision; it’s also about managing costs. Laser cutting optimizes material usage, ensuring that the maximum amount of sheet metal is utilized with minimal waste. This is especially important in industries where materials like steel and stainless steel can be expensive. By reducing material wastage and eliminating the need for extensive post-processing, laser cutting helps keep production costs low, allowing you to offer competitive pricing to your customers.

- Customization and Flexibility: Every business has unique needs, and custom metal enclosures often require specific designs to fit various applications. Laser cutting’s flexibility allows for the creation of bespoke solutions without slowing down the production process. Whether you need a small batch of highly specialized enclosures or a large run of standard designs, laser cutting can accommodate these requirements efficiently.

Enhance Your Manufacturing with Weldflow Metal Products

Are you ready to take your sheet metal enclosure manufacturing to the next level? At Weldflow Metal Products, we specialize in providing top-tier sheet metal cutting service that enhances efficiency, precision, and cost-effectiveness. Our advanced laser cutting technology, combined with our experienced team, ensures that your custom metal enclosures are produced to the highest standards and tailored to meet your specific needs.

Don’t let outdated methods hold your business back. Contact us today to learn more about how our laser cutting services can transform your manufacturing process and help you achieve better results faster. Let’s work together to bring your vision to life with the quality and efficiency that only Weldflow Metal Products can deliver.