Different Types of Specialty Molds You Need to Know

Discover the diverse world types of specialty molds and how they can elevate your projects to the next level.

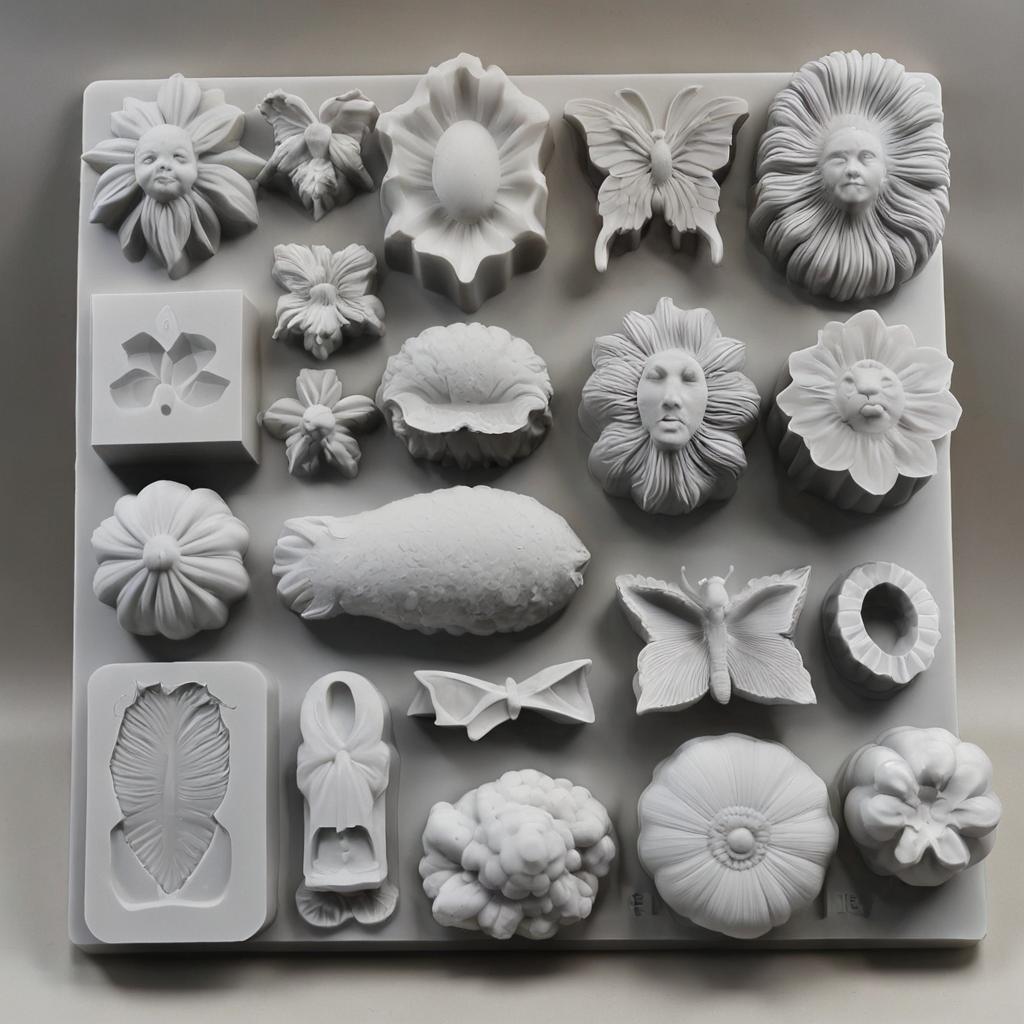

Understanding Specialty Molds

Specialty molds are unique tools used in various industries to create customized shapes and designs. These molds are specifically designed to meet the specific requirements of a project, offering endless possibilities for creativity and innovation. By understanding specialty molds, you can unlock their full potential and take your projects to new heights.

One key aspect of understanding specialty molds is knowing the materials they are made of. Specialty molds can be crafted from a wide range of materials, including silicone, plastic, metal, and even wood. Each material offers its own set of advantages and characteristics, making it important to choose the right material for your specific project.

Additionally, it’s crucial to understand the different techniques and processes involved in using specialty molds. From injection molding to rotational molding, there are various methods that can be employed to create intricate and detailed designs. By familiarizing yourself with these techniques, you can make informed decisions and achieve the desired results for your project.

Common Types of Specialty Molds

Specialty molds come in a wide range of types, each designed to cater to specific needs and requirements. Here are some of the common types of specialty molds you need to know:

1. Silicone Molds: Silicone molds are flexible and durable, making them ideal for creating complex shapes and intricate details. They are commonly used in the baking and confectionery industry to make customized cakes, chocolates, and candies.

2. Injection Molds: Injection molds are widely used in the manufacturing industry to create plastic products. They involve injecting molten plastic into a mold cavity, which then solidifies and takes the shape of the mold. This process allows for mass production of identical products with high precision.

3. Blow Molds: Blow molds are used to create hollow plastic products, such as bottles and containers. The process involves injecting air into a hollow cavity, causing the molten plastic to expand and take the shape of the mold.

4. Rotational Molds: Rotational molds are commonly used for creating large, hollow objects, such as water tanks and playground equipment. The mold is rotated slowly while heated plastic is poured inside, evenly coating the inner surface of the mold. This results in a seamless and durable product.

These are just a few examples of the many types of specialty molds available. Each type offers its own set of advantages and is suitable for specific applications. By understanding the different types of specialty molds, you can choose the right one for your project and achieve the desired outcome.

Innovative Uses of Specialty Molds

Specialty molds are not limited to traditional applications. They can be used innovatively to create unique and eye-catching designs. Here are some innovative uses of specialty molds:

1. Artistic Creations: Specialty molds can be used by artists to create intricate sculptures and art pieces. The flexibility and precision offered by specialty molds allow artists to bring their creative visions to life.

2. Architectural Elements: Specialty molds can be used in architecture to create custom decorative elements, such as ornate facades, unique door handles, and intricate moldings. These molds enable architects and designers to add a touch of personalization and uniqueness to their projects.

3. Customized Products: Specialty molds can be used to create customized products that cater to individual preferences and requirements. From personalized phone cases to custom-shaped kitchen utensils, specialty molds offer endless possibilities for creating one-of-a-kind items.

4. Prototype Development: Specialty molds are invaluable in the prototyping phase of product development. They allow designers and engineers to quickly create prototypes and test their designs before moving forward with mass production.

By harnessing the innovative uses of specialty molds, you can push the boundaries of creativity and create truly exceptional projects.

Choosing the Right Specialty Mold for Your Project

Choosing the right specialty mold for your project is crucial to achieving the desired results. Here are some factors to consider when selecting a specialty mold:

1. Material Compatibility: Ensure that the mold material is compatible with the material you will be using for your project. Different materials have different properties, and using an incompatible mold material can lead to issues such as warping or poor quality output.

2. Complexity of Design: Consider the complexity of your design and choose a mold that can accommodate the level of detail required. Some molds are better suited for simple shapes, while others excel at intricate designs.

3. Production Volume: If you require a large volume of products, choose a mold that allows for efficient and cost-effective mass production. Injection molds, for example, are often the preferred choice for high-volume production.

4. Budget: Consider your budget and choose a specialty mold that fits within your financial constraints. It’s important to strike a balance between quality and cost to ensure the best value for your investment.

By carefully evaluating these factors and consulting with experts in the field, you can select the right specialty mold that aligns with your project requirements.

Maintenance and Care Tips for Specialty Molds

Proper maintenance and care are essential to prolonging the lifespan of specialty molds and ensuring optimal performance. Here are some tips to keep in mind:

1. Regular Cleaning: Clean the mold after each use to remove any residue or debris. Use a mild detergent and a soft brush to gently scrub the mold, ensuring all surfaces are thoroughly cleaned.

2. Avoid Abrasive Materials: When cleaning the mold, avoid using abrasive materials or harsh chemicals that can damage the mold surface. Opt for non-abrasive cleaning agents and soft cleaning tools.

3. Store in a Cool and Dry Place: Specialty molds should be stored in a cool and dry place to prevent moisture buildup, which can lead to mold growth or degradation of the mold material.

4. Inspect for Damage: Regularly inspect the mold for any signs of damage, such as cracks or wear. Address any issues promptly to prevent further damage and ensure consistent quality in your projects.

By following these maintenance and care tips, you can maximize the lifespan of your specialty molds and ensure that they continue to deliver exceptional results. Shop now Candle Molds.