Benefits of Custom Workholding Fixtures for Precision Manufacturing?

Precision manufacturing is the backbone of aerospace, automotive, and medical devices, where even the slightest inaccuracies can have significant consequences. Ensuring high-quality results requires tools that enhance both efficiency and precision. One such essential tool is custom workholding fixtures. Designed to hold workpieces securely during machining processes, these fixtures improve accuracy, streamline production, and ensure operator safety. For businesses aiming to meet tight tolerances and demanding specifications, custom workholding fixtures offer an unmatched solution.

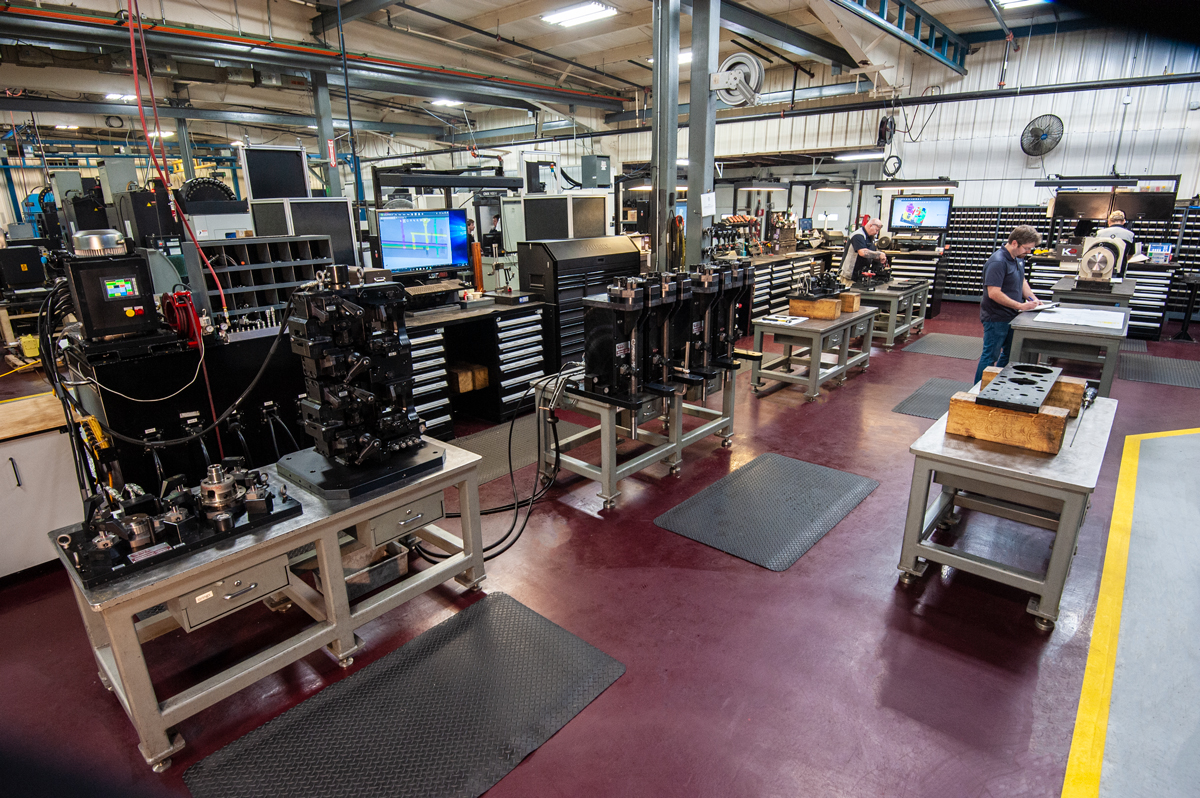

What Are Custom Workholding Fixtures?

Custom workholding fixtures are specialised tools tailored to the dimensions and requirements of specific workpieces. Unlike standard fixtures, these are engineered to provide a precise fit, ensuring stability and alignment during machining, assembly, or inspection. Their ability to eliminate inconsistencies and enhance the overall process makes them indispensable in modern manufacturing. By holding the workpiece securely in place, custom fixtures reduce errors, minimise material waste, and improve the quality of the final product.

Key Benefits of Custom Workholding Fixtures

-

Enhanced Precision and Accuracy

Custom fixtures are specifically designed to ensure the perfect alignment and stability of the workpiece throughout the manufacturing process. This minimises misalignments and errors, helping manufacturers produce components with consistent quality, even for the most complex designs.

-

Increased Productivity

The tailored nature of custom workholding fixtures reduces the time required for adjustments and setup. This efficiency translates into faster production cycles, enabling manufacturers to meet tight deadlines while maintaining high-quality standards. Faster processes also mean reduced downtime and increased throughput.

-

Improved Safety

Safety is a critical concern in manufacturing environments. Custom workholding fixtures provide a stable hold on workpieces, significantly reducing the chances of slippage during operations. This stability protects the machinery and minimises operators’ risks, creating a safer workplace.

-

Cost Savings

While the initial investment in custom workholding fixtures might be higher than standard options, the long-term savings are significant. Reduced material waste, fewer production errors, and less downtime contribute to cost efficiency. Additionally, these fixtures can prolong the lifespan of machinery by ensuring optimal alignment and reducing wear and tear.

-

Versatility

Custom fixtures are designed to handle a variety of shapes, sizes, and materials. This versatility allows manufacturers to use them across different projects, making them an economical and practical solution. Their adaptability also ensures that manufacturers can meet diverse production requirements without compromising quality.

Industries That Benefit

Custom workholding fixtures are widely used across industries that demand precision and efficiency:

- Aerospace: Essential for producing complex components with stringent tolerances.

- Automotive: Used to optimise assembly line processes and maintain consistent quality.

- Medical Devices: Critical for manufacturing intricate and precise components for healthcare equipment.

Conclusion

Custom workholding fixtures offer various benefits, including enhanced precision, improved productivity, excellent safety, and long-term cost savings. Their ability to adapt to multiple workpiece requirements makes them an indispensable tool in precision manufacturing. For businesses aiming to deliver consistent quality and optimise operations, investing in custom workholding solutions is a wise choice.

FAQ

Q1: What are custom workholding fixtures?

A: Custom workholding fixtures are specially designed tools used in manufacturing to securely hold a workpiece in place during machining. These fixtures are tailored to fit the specific geometry of the part, ensuring precise alignment and stability during the production process.

Q2: How do custom workholding fixtures improve precision in manufacturing?

A: Custom workholding fixtures are designed to securely hold parts in exact positions, reducing the likelihood of movement or misalignment during machining. This results in higher accuracy, tighter tolerances, and more consistent quality throughout production.

Q3: Why should I choose custom workholding fixtures over standard ones?

A: Custom workholding fixtures provide a better fit for your specific part design, which increases part stability and reduces setup times. They also allow for more efficient handling of complex geometries, leading to improved manufacturing performance and reduced errors.

Q4: Can custom workholding fixtures reduce production time?

A: Yes, custom workholding fixtures can reduce production time by allowing for faster and more accurate setups. With fixtures designed to securely hold parts with minimal adjustments, operators can achieve quicker cycle times and reduce the need for repositioning or recalibration.

Q5: How do custom workholding fixtures reduce defects and scrap?

A: By ensuring that parts are securely held in place and accurately aligned, custom workholding fixtures reduce the chances of misalignment or movement during machining, which in turn minimizes defects and scrap. This results in better-quality products and reduced waste.