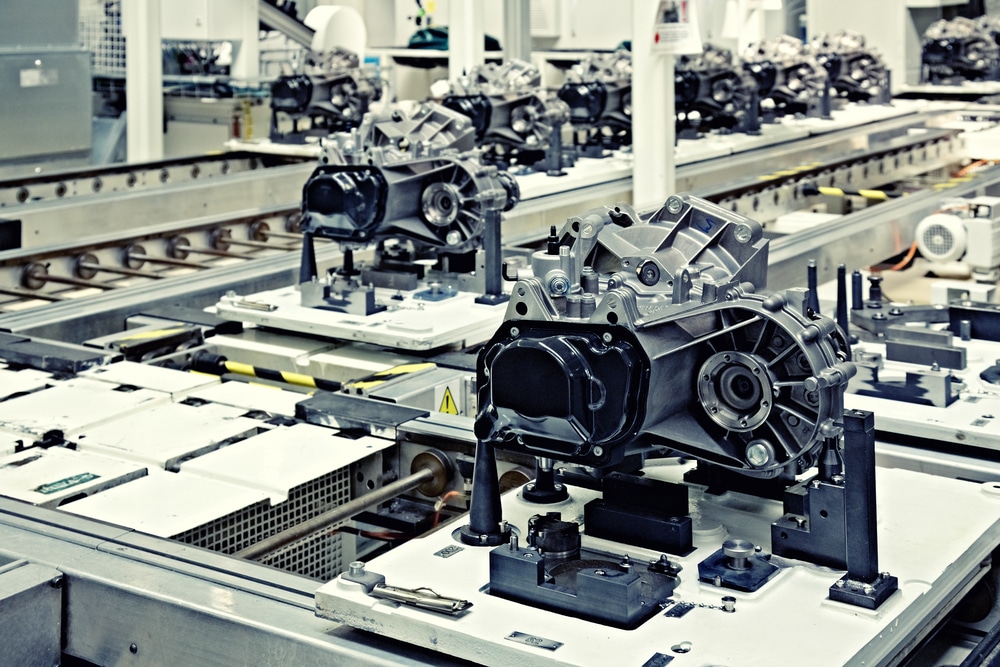

The Role of Automation in Tool Manufacturing Process

Automation is the key to enhancing the manufacturing of tools and products. In this context, automation uses cutting-edge technologies for high-level performances of tools. AI, robotics, computer-based, or advanced machines can accomplish this, thereby reducing the need for human intervention. In 2025, technology works with automation to generate quality automation control and efficiency. All the automated work prevents human errors and provides real-time solutions. Continue reading the content for more insights on quality.

The Functions of Automation in Tool Manufacturing

The roles of automation are many; to name a few, below are the major functions of automation in tool manufacturing. Implementing automated hand tools is a systematic approach that improves accuracy and customization, and reduces cost and waste, etc., Keep reading for a detailed explanation.

Product Accuracy and Real-time Solution

A small defect requires a hand tool that functions to bring an instant solution for the problem. It ensures precision during the intricate process. These hand tools are helpful in cutting and shaping. In fact, automation enhances data analysis that helps manage quality and accuracy. Such automation can drastically change the variations and defects and give less space to human errors.

Scalability

The flexible option in manufacturing hand tools allows scaling the product thoroughly. There is a high likelihood of switching tool styles and designs. The tool’s quality must be the same for all unit designs, whether 1,000 or more. Moreover, it is important to have consistent tool manufacturing automation.

Quality Control

The tool product must have quality management with speed and high productivity. It is essential to have faster production and high output rates to satisfy the customers. From the beginning of the manufacturing to the end, the process should be standard.

The measurements, styles, cuts, and all other requirements are present to deliver an accurate automated product. The usage of material and tool quality is also essential to provide the finest product.

Minimizes the Waste

When humans are involved in manufacturing, the waste has no limit. But, after the invention of the automation machine, it consumes time and wastes efficiently. Automation machines have optimized cutting and maximized material utilization in manufacturing. This is one of the important roles of tool manufacturing that helps the product remain competitive in the automation industry.

Makes Cost efficient

Tool manufacturing through automation methods reduces cost and saves you money when compared to labour. For example, a progressive die company produces metal parts in high volumes.

Automation helps this company by being cost-efficient and standard in quality. Its roles include minimizing errors and labour costs and ensuring efficient use, all while manufacturing within a limited time frame. Therefore, this automated process optimizes waste use and provides standard output.

Testing and Integrating

Basically, before making a product, it is important to research, assemble, and draft the designs. In fact, testing the product is crucial before the final release. The tool manufacturer is keen on optimizing their automation process to design, integrate, test, and validate. The integration process involves optimization and compatibility with the tool. It helps to meet the desired quality, standard, and performance of the product.

Reduces Errors and Rework

Reduction of errors is one of the important roles of quality automation in tool manufacturing. The product made during the automation process will have fewer errors and defects. There is no space for reworks and mistake detection. Even if there are any mistakes, they can be rectified prior to the final production.

High Productivity

Automation increases the production of tools and other products. It consumes less time and provides more services. Automated hands always foster productivity, speeding up processes from design to packaging.

Final Thoughts

The role of automation in tool manufacturing is described above. It demonstrates how automation replaces human labour to produce products efficiently. Automation demonstrates the production of progressive dies, metals, and hand tools. The roles of automation involve quality control, scalability, minimizing waste, reducing costs, etc. Therefore, it is important to select the appropriate automation technology for tool production. Are you looking for the right service? Explore the automotive stamping capabilities at Eigen Engineering. They have been offering tool and die design engineering services and other diverse category and expert services for 14 years. Hurry up to start your productive service at Eigen Engineering.