How Long Will CBD Dropper Bottle Boxes Last

CBD dropper bottles have gained popularity in recent years due to the increasing interest in the benefits of cannabidiol. With this rise in demand, packaging has become an essential aspect of marketing and presentation. Specifically, CBD Dropper Bottle Boxes play a crucial role in protecting the product while also conveying information to consumers. This guide will explore the various aspects of CBD dropper bottle boxes, including their purpose, design considerations, materials, and production.

Understanding the Purpose of CBD Dropper Bottle Boxes

The primary purpose of CBD dropper bottle boxes is to protect the bottles during storage and transportation. These boxes provide a barrier against physical damage, such as impacts or scratches, which can occur during shipping or handling. Proper packaging ensures that the product reaches the consumer in excellent condition.

Design Considerations

Size and Shape

When designing CBD dropper bottle boxes, the size and shape must fit the specific bottle being used. The box should snugly accommodate the bottle to prevent movement during transit. Custom dimensions are often necessary, as dropper bottles can vary in height and width.

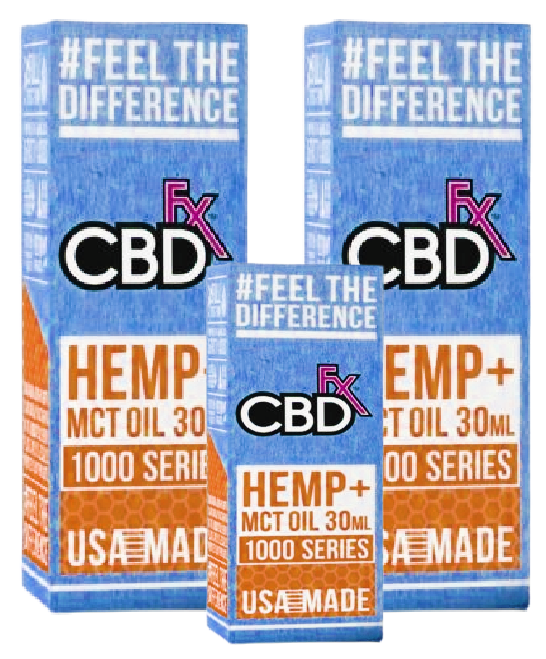

Graphics and Branding

The graphics on the box should reflect the brand identity and appeal to the target audience. This includes choosing colors, fonts, and images that align with the overall branding strategy. The design should be eye-catching yet clear, ensuring that essential information is easily readable.

Information Display

The box should clearly display important information about the CBD product. This can include:

- Product Name: Clearly stating what the product is.

- Dosage Instructions: Providing guidance on how much to use.

- Ingredients: Listing the components of the CBD oil.

- Certifications: Indicating if the product is organic, non-GMO, or third-party tested.

Including this information not only helps consumers make informed choices but also builds trust in the brand.

Material Options

Choosing the right material for CBD dropper bottle boxes is crucial for both protection and presentation. Several materials are commonly used in packaging:

-

Cardboard

Cardboard is a popular choice for CBD packaging due to its versatility and cost-effectiveness. It is lightweight yet sturdy enough to protect the bottles. Cardboard can also be easily printed on, allowing for vibrant designs that attract consumers.

-

Rigid Boxes

Rigid boxes offer a premium feel and are more durable than standard cardboard boxes. They provide excellent protection for high-end CBD products and can create a luxurious unboxing experience for customers. While they are generally more expensive to produce, the investment can pay off by appealing to a market that values quality.

-

Eco-Friendly Materials

With increasing awareness of environmental issues, many brands are exploring eco-friendly packaging options. Materials like recycled cardboard or biodegradable alternatives can help reduce the environmental impact of packaging. Using sustainable materials can also resonate with consumers who prioritize eco-conscious products.

Production Process

The production process for CBD dropper bottle boxes typically involves several steps. Understanding these steps can help brands ensure they choose the right production method for their needs.

-

Design and Prototyping

The first step in production is designing the box. This includes creating graphics and determining dimensions. Many companies use design software to create digital mockups, allowing for easy adjustments before finalizing the design.

-

Printing

After finalizing the design and prototype, the next step is printing. Different printing methods can be used, such as digital printing or offset printing. Digital printing is often more cost-effective for smaller runs, while offset printing may be preferred for larger quantities due to lower per-unit costs.

-

Cutting and Assembly

Once printed, the material is cut to the required shape. Hence, this process can be done using die-cutting machines, which provide precise cuts for consistent results. After cutting, the boxes are assembled, either manually or through automated processes, depending on the scale of production.

-

Quality Control

Quality control is an essential step in the production process. This involves inspecting the printed boxes for any defects, such as misalignment or printing errors. Ensuring that each box meets quality standards is crucial for maintaining brand integrity.

Regulatory Considerations

When producing CBD products, it is essential to be aware of regulatory requirements. Packaging must comply with local and federal regulations regarding labeling and safety. This includes providing accurate ingredient lists and dosage information, as well as adhering to any specific claims made on the packaging.

Marketing and Promotion

Once the packaging is produce, it plays a vital role in marketing the CBD product. Effective use of packaging can enhance brand visibility and attract new customers. Here are some ways to leverage packaging in marketing efforts:

-

Shelf Appeal

Packaging is often the first thing a customer notices. A visually appealing design can make a product stand out on crowded shelves. Investing in unique designs and high-quality materials can capture consumer attention and encourage purchases.

-

Social Media

In today’s digital age, packaging can also serve as a marketing tool on social media. Encouraging customers to share images of the product with its packaging can enhance brand awareness. Brands can create specific hashtags or campaigns to promote user-generated content.

-

Information and Education

Using the packaging to educate consumers can also be beneficial. Including information about the benefits of CBD, how to use the product, and any scientific backing can enhance the perceived value of the product. Consumers appreciate brands that provide transparency and knowledge.

Conclusion

CBD dropper bottle boxes are an essential component of product presentation and protection. They serve multiple purposes, from safeguarding the product during transport to conveying important information and marketing the brand. By considering the design, material options, production processes, and regulatory requirements, brands can create effective packaging that resonates with consumers. Custom Packaging Boxes can elevate your product’s presentation and ensure it stands out on the shelves.