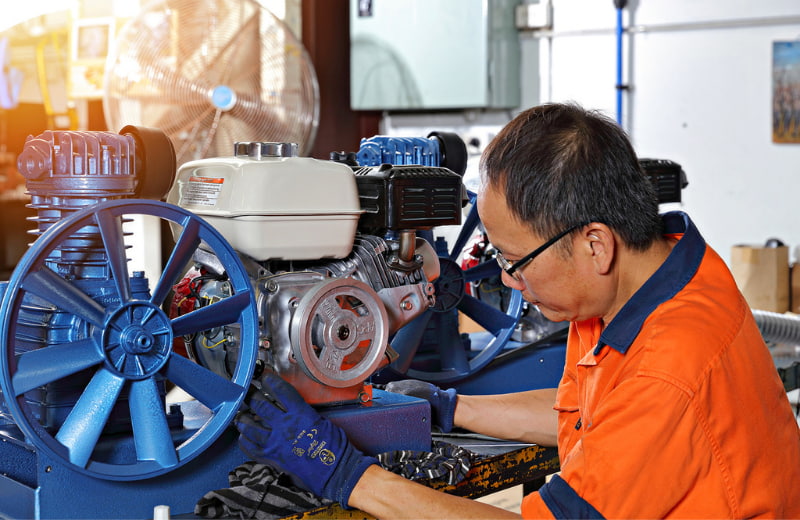

6 Steps to Perform Routine Air Compressor Maintenance

Regular maintenance is essential to keep your air compressor running efficiently and to prolong its lifespan. Neglecting maintenance can lead to costly repairs and downtime. Here are six steps to perform routine air compressor maintenance effectively.

1. Check and Change the Oil Regularly

Oil is vital for the smooth operation of your air compressor. Check the oil level before each use and top it up if necessary. Change the oil every 500 to 1,000 hours of operation or as the manufacturer recommends. Using the right type of oil is crucial. Clean oil ensures the compressor runs smoothly and reduces wear and tear on internal components. Regular oil changes help maintain optimal performance and extend the compressor’s lifespan.

2. Replace the Air Filter

A clean air filter is essential for efficient operation. Inspect the air filter monthly and replace it if it’s dirty or clogged. A dirty air filter restricts airflow, causing the compressor to work harder and consume more energy. Replacing the air filter regularly helps maintain efficiency and prevents dust and debris from entering the system. This simple step can significantly improve the performance and longevity of your air compressor.

3. Inspect and Tighten All Fasteners

Vibrations from the compressor can loosen bolts and nuts over time. Inspect all fasteners regularly and tighten them as needed. Loose fasteners can lead to leaks and mechanical failures, reducing the compressor’s efficiency and potentially causing damage. By ensuring all components are securely fastened, you can prevent operational issues and maintain the reliability of your system.

4. Drain the Moisture from the Tanks

Compressed air systems generate moisture that can accumulate in the tanks. Drain the moisture daily to prevent rust and corrosion. Moisture in the tanks can lead to rust, which can damage the compressor and contaminate the compressed air. Draining the tanks regularly is a simple but essential maintenance task that protects your equipment and ensures clean, dry air for your applications.

5. Inspect Hoses and Connections

Regularly inspect hoses and connections for signs of wear, leaks, or damage. Replace any worn or damaged parts immediately. Leaky hoses and connections reduce the efficiency of your air compressor and can lead to significant energy losses. Keeping hoses and connections in good condition ensures that your compressor operates at peak efficiency and reduces the risk of unexpected downtime.

6. Schedule Regular Professional Inspections

While routine checks are essential, professional inspections are also crucial. Schedule regular inspections with a qualified technician to ensure your compressor is in top condition. Professionals can identify potential issues you might miss and provide expert maintenance and repair services. Regular professional inspections help prevent major breakdowns, extend the lifespan of your compressor, and ensure safe operation.

The Role of Chiller Cooling Towers in Air Compressor Systems

In addition to regular air compressor maintenance, understanding the role of chiller cooling towers is crucial for maintaining the efficiency and longevity of your compressed air system.

Managing Heat Generation

Air compressors generate considerable heat during operation. If this heat is not adequately managed, it can lead to overheating, which can damage the compressor components and reduce the overall efficiency of the system. Chiller cooling towers help dissipate this excess heat, ensuring the compressor operates within the optimal temperature range.

Enhancing System Efficiency

Efficient heat dissipation is key to maintaining the performance of an air compressor. When the compressor runs cooler, it operates more efficiently, consuming less energy. This efficiency translates into lower operational costs and improved productivity. Chiller cooling towers enhance the overall system efficiency by providing a stable cooling solution that keeps the air compressor at an optimal temperature.

Preventing Equipment Wear and Tear

Overheating can cause wear and tear on compressor components, leading to frequent breakdowns and costly repairs. Chiller cooling towers help mitigate this risk by maintaining a consistent cooling environment. By preventing excessive heat build-up, these cooling towers protect the internal components of the air compressor, such as valves, seals, and bearings, from premature wear.

Improving Air Quality

The temperature of the compressed air can affect its quality. High temperatures can lead to moisture build-up and contaminants, negatively impacting the performance of air-powered tools and equipment. Chiller cooling towers help maintain a lower temperature, reducing moisture and ensuring cleaner, dryer compressed air.

Supporting High-Demand Applications

Air compressors often run continuously in industrial settings with high-demand applications for extended periods. This continuous operation can generate substantial heat, requiring an effective cooling solution to prevent overheating. Chiller cooling towers provide the necessary cooling capacity to support these high-demand applications, ensuring the air compressor can operate efficiently without interruptions.

Integration with Existing Systems

Modern chiller cooling towers are designed to integrate seamlessly with existing air compressor systems. They can be customized to match the specific cooling requirements of different compressor models and configurations. This flexibility allows businesses to implement a cooling solution that fits their unique operational needs.

Routine Maintenance of Cooling Towers

Like air compressors, chiller cooling towers require regular maintenance to perform optimally. Routine tasks such as cleaning the cooling tower, inspecting the water quality, and checking for any signs of wear or damage are essential. Regular maintenance ensures that the cooling tower operates efficiently and provides the necessary cooling capacity to the air compressor.

Conclusion

Performing routine air compressor maintenance is essential for ensuring efficient operation and prolonging the lifespan of your equipment. Following these six steps can maintain optimal performance and prevent costly repairs. Don’t forget the importance of chiller cooling towers in managing the heat generated by your compressor system. Ready to enhance your air compressor maintenance routine and ensure peak efficiency? Visit Complete Engineered Solutions for expert advice and advanced solutions tailored to your needs. Take the first step towards reliable and efficient compressor operation with Complete-ES.