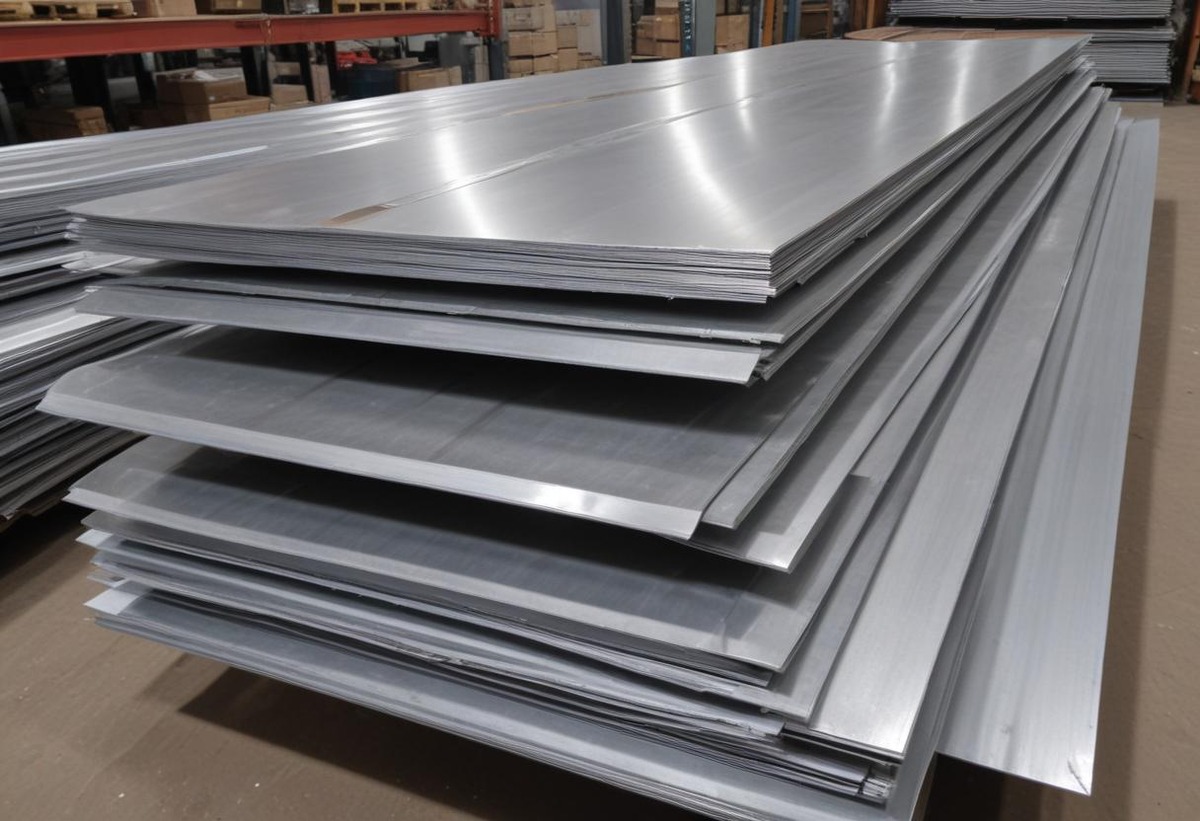

10 Quality Control Measures Implemented by Reputable MS Plate Suppliers in the Philippines

In the process of producing steel-based products, quality control is required to produce materials that are meant to be durable and worthy. MS plate suppliers in the Philippines maintain strict quality control measures so that high product standards comply with industry standards. As a result, a COP of absolute-domain necessity is the quality criterion for MS plates, which are used in manufacturing, construction, and other related industries to guarantee performance and safety. Any project using these materials has to select reliable suppliers who follow strict quality control procedures.

Raw Material Inspection

The MS plate suppliers initiate quality control by carefully inspecting the raw materials. This essential process on its own ensures that the raw materials adhere to predefined standards before they are sent on to make the MS plate. The suppliers will first inspect the raw materials for any deviations from the specified quality standards. Then and only then will they guarantee consistency and dependability in the completed MS plate products that they deliver to their clients.

Chemical Composition Analysis

As a quality control measure, MS plate suppliers respond to this by conducting a thorough chemical composition analysis. To guarantee that the elements in the materials have the exact composition, precise test procedures are used. It guarantees that the suppliers, who possess the proper chemical composition, pay attention to the necessary qualities in MS plates to give them the proper resistance to corrosion and strength. This is an extremely important analysis because, in many applications, even minute changes in chemical composition can have a major effect on performance and plate life. Strict industry standards are met and product integrity is preserved by suppliers with the aid of meticulous chemical testing.

Mechanical Property Testing

Testing for mechanical properties is one of the quality control measures undertaken by MS plate suppliers. This test shall determine the following vital characteristics: tensile, hardness, and impact properties. A supplier shall, through these tests, be able to identify or ensure a certain material’s qualification to meet desired performance. Tensile strength is how much load a material can undertake before it breaks, whereas hardness is a resistance imparted by superficial indentation. The impact resistance tests measure the resilience of the plates to any sudden force or shock. A test such as this would be performed to make sure that under various kinds of operating conditions, MS plates maintain their essential structure and reliability.

Dimensional Accuracy Checks

One of the crucial steps in the quality control procedures that MS plate suppliers adhere to is checking for dimensional accuracy. This step involves properly verifying the plates’ geometrical characteristics and physical dimensions. It guarantees that the thickness, width, length, and other geometric measurements are accurately verified by the specifications in the MS plate that the supplier provides. To ensure that the plates fit, work, and remain structurally sound under various conditions, precise dimensions are essential. Suppliers implement strict controls to verify that the products meet customer specifications or project requirements, including checking dimensional accuracy.

Surface Quality Inspection

MS plate suppliers introduced the essential quality control measure of surface quality inspection. The process involves closely examining the plate surfaces to look for any flaws or irregularities. Suppliers employ visual inspection and other contemporary techniques to detect surface imperfections such as cracks, scratches, and rust spots on the MS plates. To improve MS plates’ visual appeal and practical value, they must have flawless, smooth surfaces. Suppliers make sure these plates have no surface flaws, making them suitable for further processing, welding, painting, or other uses where the surface condition is crucial. This meticulous inspection procedure makes it possible to supply MS plates for services that demand high-quality aesthetics in addition to functionality.

Non-Destructive Testing (NDT)

Another crucial quality control test that an MS Plate supplier follows is to check the integrity of the material without damaging it. Magnetic particle, radiographic, and ultrasonic testing are examples of non-destructive testing methods. When utilizing these nondestructive testing techniques, suppliers guarantee that MS plates maintain their structural integrity and dependability. They enforce strict quality standards before using them in critical applications.

Heat Treatment and Process Control

Process control and heat treatment are essential components of quality assurance in MS plates from any provider. To achieve mechanical properties like hardness and strength, we induce cycles of heating and cooling. They keep a close eye on the same, paying particular attention to consistency at first, and then uniformity across batches, so that these MS plates satisfy strict durability requirements in both manufacturing and construction. Effective process control ensures that the properties of the plates conform to the specifications provided by the customer.

Certification and Documentation

Certification and documentation are the first steps in quality control for MS plate suppliers in the Philippines. Suppliers use the offered certificates to prove that their plates satisfy customer requirements and industry standards. These documents include test and inspection results from various phases of the plate’s production process. In a sense, they uphold transparency and encourage traceability, giving consumers a way to verify the caliber of the product and compliance with laws. Complete documentation aids in resolving any quality concerns that may arise after delivery. Ensuring that suppliers of dependable MS plates can meet regulatory requirements and quality standards requires meticulous record-keeping.

Packaging and Handling Standards

Properly packaging and handling MS plates is essential to preserving their quality during transit. Suppliers of MS plates take precautions to prevent contamination and corrosion from affecting their physical state. They handle these delicate materials with care, following specific protocols for safe handling and storage that lessen the chance of deterioration or damage. Suppliers must correctly trace every shipment for safety, requiring proper labeling and documentation. They follow a strict packaging and handling routine to ensure MS plates arrive in the best condition for any application.

Regular Audits and Continuous Improvement

MS plate suppliers in the Philippines must therefore take into account areas for continuous improvement as well as recurring audits. Internal and external audits ensure compliance with industry standards, and the company identifies geographical weaknesses to facilitate process improvement. They request and examine customer feedback to make changes to the products. Programs for continuous improvement put an emphasis on improving productivity, lowering errors, and creating new production techniques. Though the industry changes, suppliers can reassure customers of their dedication to premium MS plates through correct and frequent practices. This also guarantees customer satisfaction.

Key Takeaway

Quality control is crucial for any reliable MS plate suppliers in the Philippines. Pruning occurs at various levels, including raw material inspection, analysis, mechanical property testing, and ensuring dimensional accuracy and product quality. Additional quality controls for heat treatment, non-destructive testing, and surface quality inspection ensure dependability and efficiency. Certification, suitable packaging, and periodic audits ensure the validation of this fundamental principle. By adhering to stringent quality control procedures, MS plate suppliers offer dependable, long-lasting materials, satisfying diverse industry needs and clientele.